Design

The designing process has been evolving since we established this company and started designing bathware like tubs, sinks and basins. We have been adopting customers’ demand and what kind of designs they like the most. We study latest trends carefully for inspiration that results in amazing products.

We collaborate with interior designers of 5-star hotels and resorts and combined with our skills and experience in manufacturing Acrylic Solid Surface products, we create stylish bathtubs, sinks and other bathware. As designing is the first step, we spend lots of time there.

Mold opening

Opening mold needs precision and it is one of the most important steps of the entire procedure. MDF, putty and resin bond together and developed into the master mold that defines the basic structure of the product. Master mold should be according to the drawing to be ready for the next step.

The next step involves fiberglass to be embedded into the master mold in around 20 different layers. These layers are tightened together using fine quality resin that increases the overall durability and lifespan of the product.

Mold making is a complex process that not only needs skills and precision but also requires years of experience to get a fine product at the end.

- A bathtub mold may require 2-3 experienced workers and up to 30 days to finish.

- If a product does not pass our quality test, we start the process from the beginning. The final product must be durable and accurate in shape, design and size.

Acrylic Solid Surface as Base Material

1.Not only plane colors like white, yellow, black, red and others, but it can be mixed with other colors as well that means customers can order any color of their desire.

2.Unlike granite, solid surface tend to have a gentle outer surface that results in easy sanding and polishing processes. On the other hand, it also makes it easier for customers to maintain the products.

3.Solid Surface is known to have smoother and silkier surface as compared to ceramic. It also gives warm feelings on touching bathware.

4.Because Solid Surface products are non-porous, bacteria cannot grow in them

5. STONETECO bathware products are easy to clean by even normal household cleaning agent. For immovable stains, you can use sanding sponge that doesn’t damage the tubs or basins.

After couple of years of use, you can do re-sanding and polishing to make years-old bathware like brand new

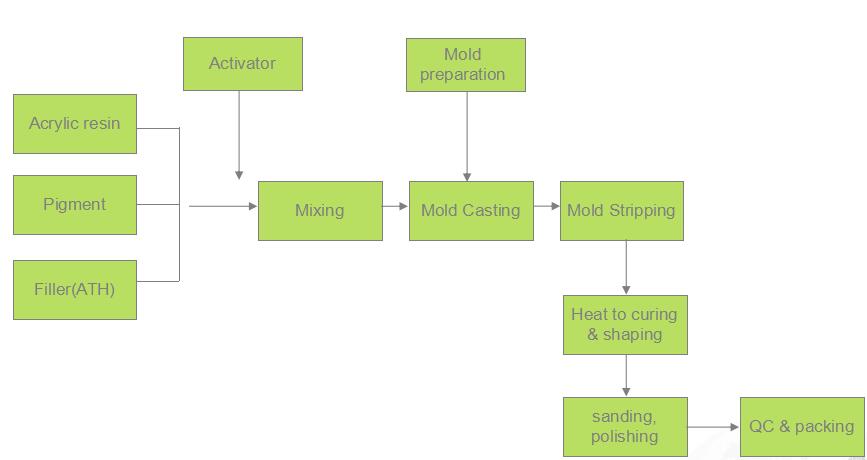

Production flow

1.Designing and creating precise mold

2.Use exact formula for combining resin, filler, pigments and other items depending on the product.

3.Put that mixture into the mold and this process usually takes less than an hour.

4.Put the raw product on 90C heat for almost 2 hours and wait for it to cool down.

5.Sanding and polishing the products manually until it gets the desired shape, design and smoothness.

6.Check the product thoroughly for any defect and forward passed products to packaging process.

Quality Checking

To ensure highest quality and reduce the chances of human error, we use IPQC system (In-Process Quality Control) that allows us to examine every product we make during every step it goes through. We check these using powerful floodlights to detect any impurity, defect or imperfection like sanding marks.